I dont have my old notes anymore. They sent them with my original set of brewing equipment when I sold it. However, from what I remember, it was an Octoberfest (or Marzen style) and I used a liquid yeast. I struggled with getting the fermentation started.

It was summertime in South Carolina; so it was hot. When my yeast arrived, the icepack had melted and the package was hot and bloated a little. I think my interpretation of the instructions were to pitch the yeast around room temperature and then take the temp down to fermenting temp over the course of a day.

I had a temperature controlled refrigerator so I pitched the yeast and hoped for the best. It did start fermenting, so I put it in the refrigerator and fermenting stopped. I think I tried it two or three more times to the point where I gave up and let it finish out at ale (room) temperature.

I guess to be technical, the brew didn’t fail. It just didn’t ferment at lager temperatures. It certainly didn’t result in what I wanted, because of the temperatures and I contrasted liquid versus dry yeast yesterday. This time, I thought that I would make a yeast starter to kick start my anticipated sluggish start.

Just like making bread, you get the yeast hydrated and give it some food. This in theory makes it ready to take off when pitched. So, I thought I would give it a shot.

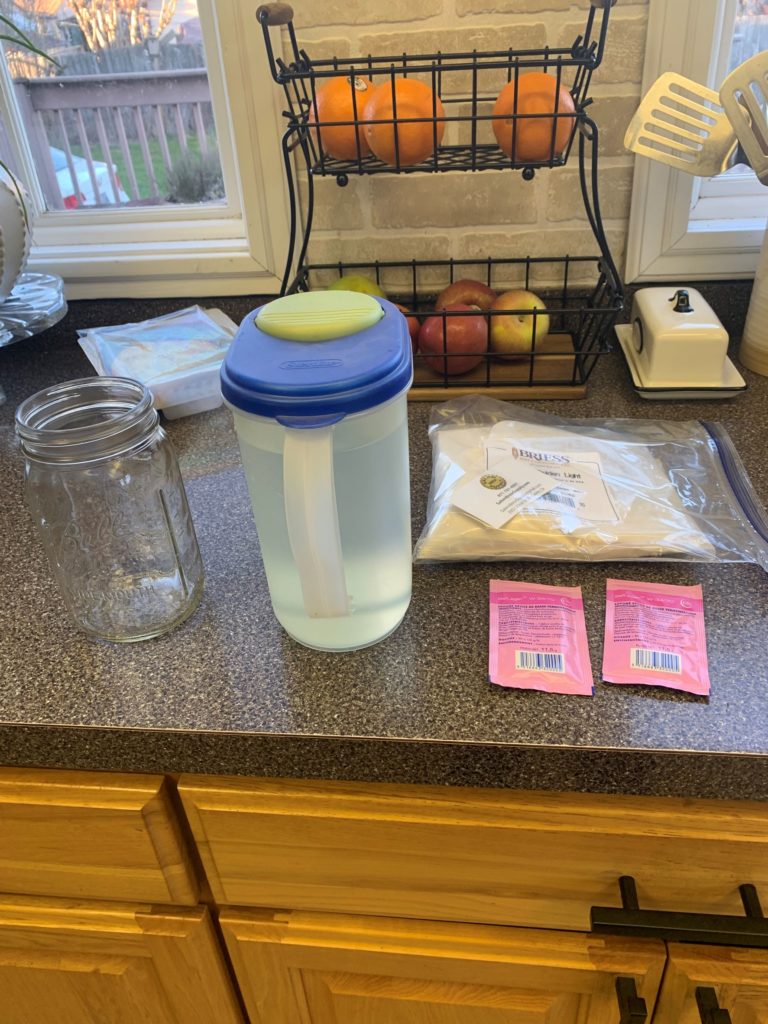

Making a starter is a micro beer batch.

- A container with lid

- Yeast

- Malt Extract

- Sanitizer

- Water

This is probably a place where using Malt Extract makes sense even if you are doing whole grain brewing. In fact, yeast can be re-used if you are going to immediately start brewing the same style of beer. It can be stored in the refrigerator, in a sanitary container for a couple of weeks. I have never had enough space or bottles to do sequential brewing but it is a place to save $12 a batch if you were going to do such a thing. Maybe with this new kegging system I will speed up production volume?

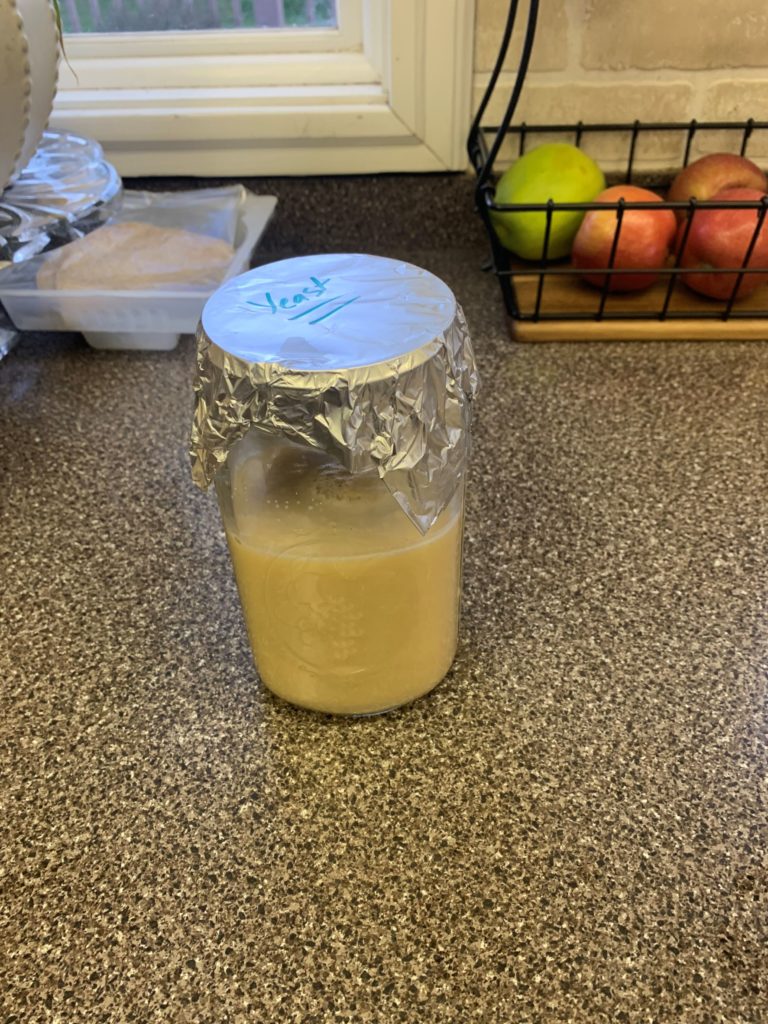

Heat up water to boiling, pour into a sanitized container. Add 1/2 cup of malt extract and dissolve. Cool the liquid down to pitching temperature. Add the yeast and top the container with a sanitized lid (that will let CO2 out). Do this two up to two days before brewing and that is it. I did it the day before I brewed.

End Your Programming Routine: The reality is, I don’t know if this was the trick or the fact that the yeast was dry, not cooked or the brewing temperature is a little warmer than my Marzen attempt. The wort was fermenting the next morning. I won’t concretely say this is the way to go but I am pretty sure this is the fastest I have ever seen fermentation kick-off. Usually, it really starts going day 2.

Recent Comments