Again, I have another packed week. I am working behind the scenes on content that is taking some time that I would normally dedicate to this effort. This is another week that I am leaning toward putting my effort into Friday instead of making sure I have something every day. I thought today that I would start with the logical first steps of brewing which are the steps that I use to get prepared and a few odds and ends that are related.

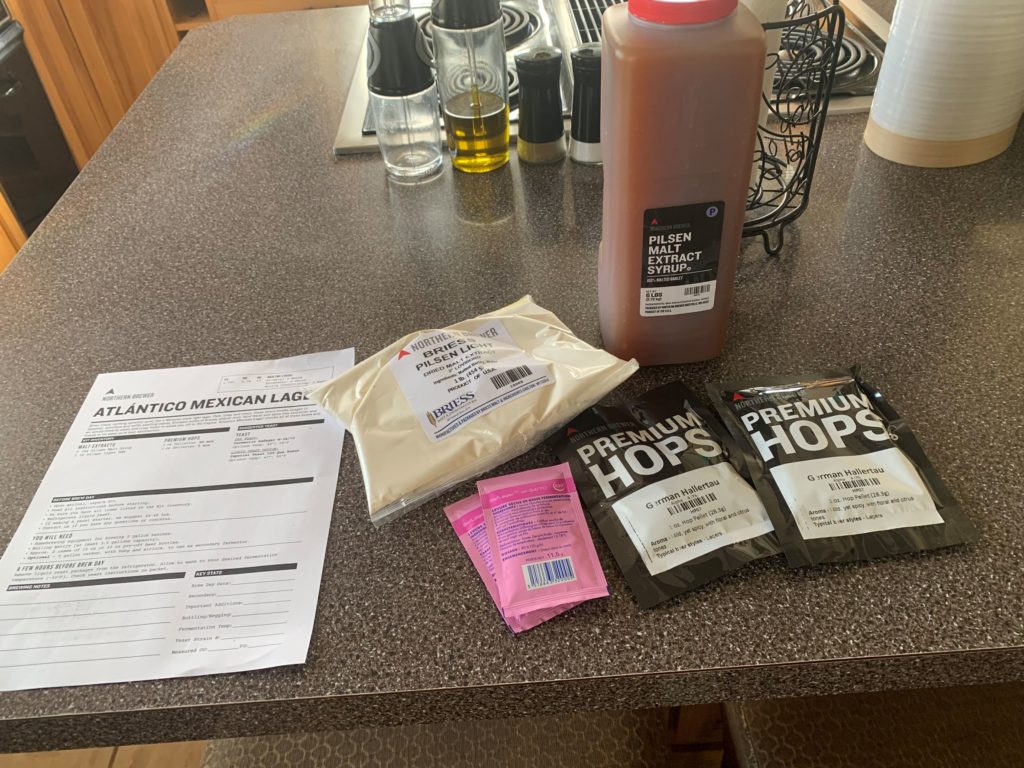

First, I thought that I would talk about what a brew kit looks like. The picture of the contents are below but essentially it is a recipe with all of the ingredients already measured out and packaged together ready to go.

This is a pretty simple recipe: Malt extract, hops and yeast. What is missing is the water. The kit provider also supplies a ‘one sheet’ of precise instructions, including a place to write notes and to keep this as a permanent record. I have my own notebook that I use but for people getting started or less disciplined, this can be really handy.

This kit is characterized as extract brewing. What this really means is that one of the major steps in brewing has already been done. Malting takes a whole grain and steeps it in water. This causes the seed to begin to germinate. That process converts the stored starches into sugar by activating natural enzymes and the sugar is what is fermented.

Malting barley can also be done by the home brewer. It requires a more significant equipment investment and more time. This is something that I actually have the equipment and is on my radar for experimentation but has been stuck behind a lot of other things that I would rather do. This is getting me motivated to step it up however.

Malt extract is made by a manufacturer malting the barley by concentrating the sugar (liquid) or evaporating the water (dried). I find the dried easier to handle but I think the liquid makes a better end product. The other prime limitation of the liquid is that it seems to come in either 1.5kg (3.3 lbs) or 6lb containers. That means that often the brewer uses some of both in a recipe.

Yeast is the mojo that makes it work. Yeast is the trade secret in all beer makers businesses because it can be adjusted and modified and is really the unknown. In the past, I used exclusively liquid yeast. In theory and definitely in cost, it is superior to dried yeast. The downside to liquid yeast is that it can get too hot, shipping in the summer can literally cook it, despite the ice packs they tried to use.

I said last week my experience with homebrewing beer has left me less than satisfied. That has driven me towards not spending the extra money on liquid yeast and this batch is no exception. Since my previous attempt at lager brewing failed (it didn’t ferment at the low temperature a lager is supposed to but it did go once I let the batch come up to room temperature), I didn’t feel like risking the money for a perceived better result. I think I have made myself clear.

End Your Programming Routine: I am planning on talking about what I am doing differently this time, tomorrow. So, if you are interesting in this topic, stay tuned. Remember what my goals are? See if the Keezer is worthy of getting integrated into the wine cellar design and while I am at it, brew a lager. Hopefully, I will get to all grain brewing and the point where I can tell the difference between the ingredients, but that is too many variables right now.

Recent Comments