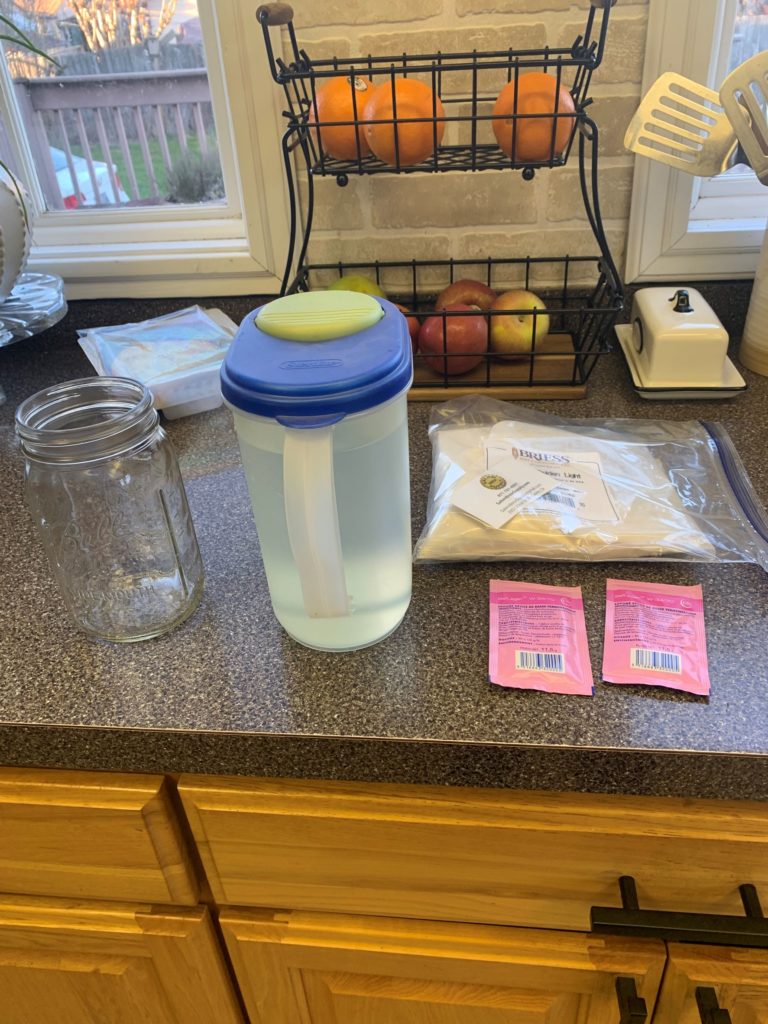

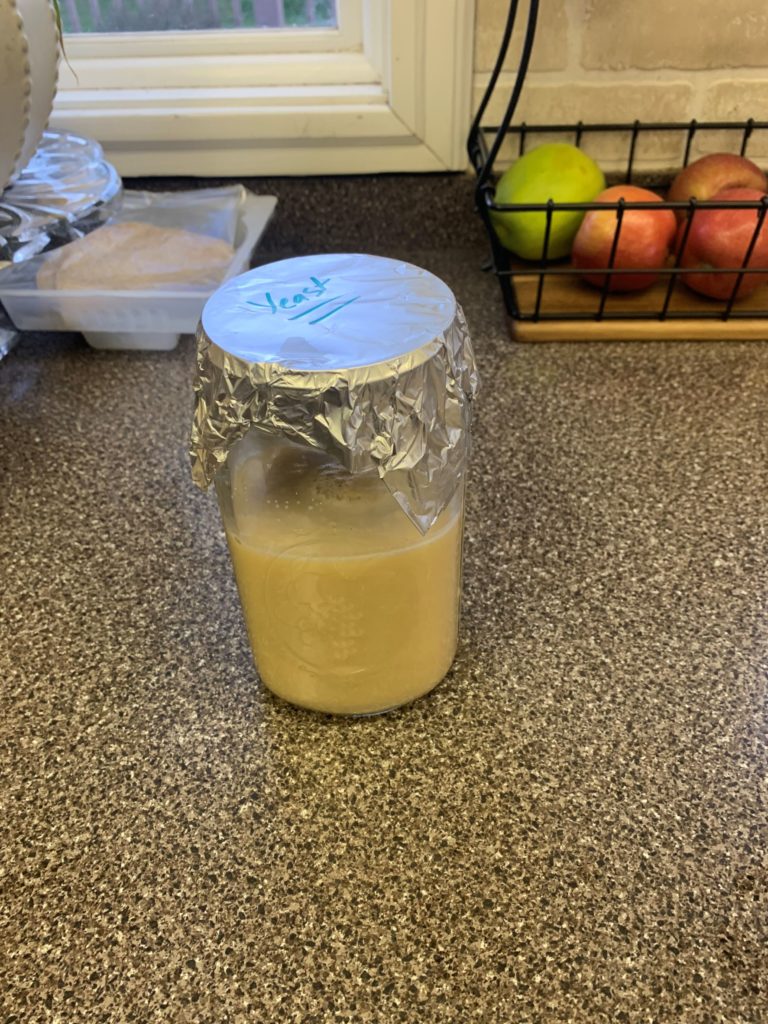

I know the dust hasn’t settled yet on my last one but I have enough bottles to do another batch. And, I wanted to do another lager while the temperature is cool to prove to myself this wasn’t a fluke. Third, I am going to re-pitch the yeast from my Mexican beer so it will save me $13 on this batch.

I ordered a Mai Bock kit. I know, another kit but I am not quite ready to go full fledged grain brewing yet. I need to prove to myself that I can do things consistently and to my expectations before I take the next step. I don’t think it will be too long at this point. I envision kits and extract brewing to be miles simpler and quicker as well. I certainly don’t need more complications to add to my life.

Mai translates to May in German. It is sometimes called helles as well and is know as a festival beer. Think the spring counterpart to Marzen (or Octoberfest). I feel like celebrating the change of seasons. Mostly, I wanted a different style that uses the same yeast as my Mexican lager and this was it.

This one is going to be even simpler than the last one. There is only one hop addition at the beginning of the boil. Maybe I should back up a quick minute on brewing in general. I know that I haven’t talked about it a whole bunch, only aspects of brewing.

You start with boiling some water. The books recommend half of the overall water. I generally do less because of pot size and I can add hotter wort to colder water and spend less time cooling. It does come with downsides because the more concentrated the wort, the less of the alpha enzyme (hops) transfer. I have tried to add additional hops in the past to the boil to try and compensate.

As I was saying, boil some water, add some malt extract, add some hops if using adjuncts (other grains and flavorings) and boil for the time the style dictates. Cool down to pitching temperature, top off with additional water for the total batch size and add yeast. That is it for brewing. Bottling or what to do with it when it is finished is a whole separate topic.

My Mexican lager is now ‘lagering’. Lagering is a rest and clarification period that occurs after brewing. I will hold it in the keezer around 35 degrees for a month and then it will be ready for kegging. If I do my math correctly, that means it should be ready somewhere in early April. This means that my fermenting carboy is open, I have bottles ready to go and I have one more secondary carboy for lagering. Sounds like an invitation to brew again.

End Your Programming Routine: This is how I get myself into trouble. I have a tendency of having too many experiments going without having results yet. Using reloading as an example, I have loaded all of my empty brass without really shooting any of it. Right now, I don’t know if I have to make any tweaks yet. This is one reason why I haven’t pushed it too hard because I need a chance to observe what I have done. But, if we are not challenging ourselves, then are we really continually learning?

Recent Comments