I am mulling around an idea (I will get to in a minute). I have talked about how we are paying to have our fence replaced. We have signed the contract and put down half of the money. I think it is going to be another month or so before it actually happens.

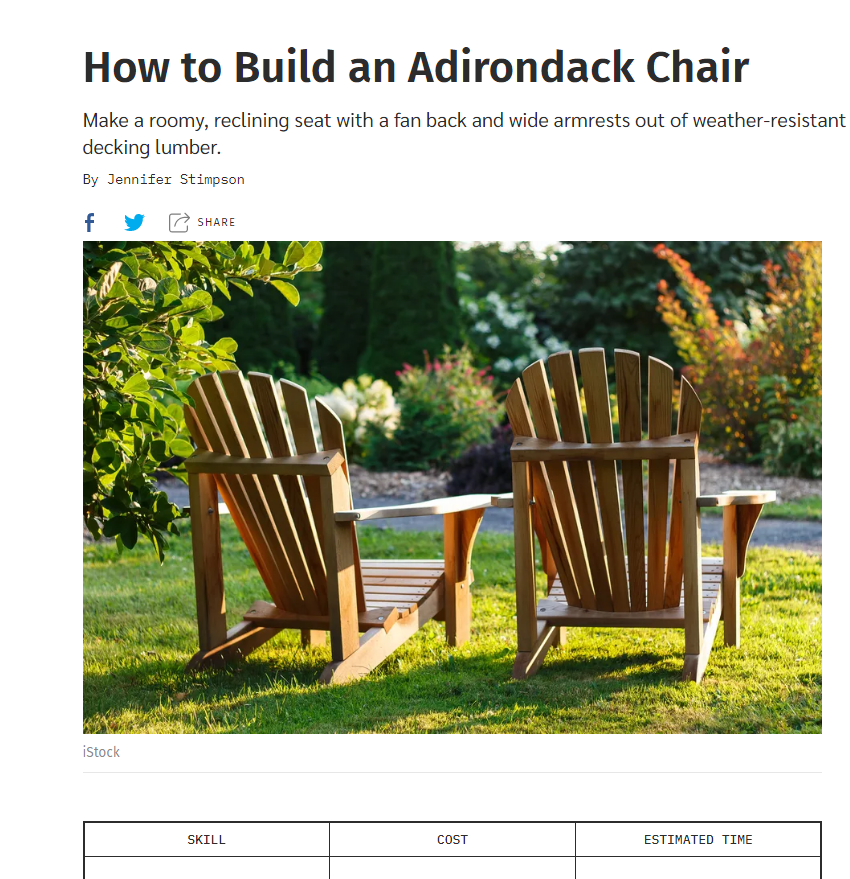

Switching gears for a minute, we were at our wine pick-up last weekend and sitting in some plastic Adirondack chairs enjoying the weather, music and some samples. We had one (or two chairs) of our own that lasted about a year. I think they came from Dollar General and the sun will destroy that cheap plastic. The chair broke and it went to the landfill.

My wife was talking about how she likes the wooden ones, but that they were expensive. That got my mind working. If I salvaged some of the fence boards, I would have a good start on material to build my own chairs. Ideally, I would be selective and take the best ones. But this all depends…

The whole deal includes tearing down the old fence. If this happens while we are home, then of course I don’t think they will mind me taking some of the waste (and picking my boards). If it happens while we are in Spain, I may miss the boat on this whole thing.

The truth is, I would like to do some test work and see if the boards can even be salvaged, but, I don’t want to tear the fence down to do so. I think I can run them through the planer and resize and they would be fine for making plenty of chairs. I do have some reservations however.

Looking at the fence, none of the boards are clear (knot free). Some of them are pretty rough. I suspect that there is going to be a high degree of waste due to wood failure or brittleness and deep weather wear. But, I won’t know that until I do some test work.

The other thing I am not sure of is they are cedar. Depending on the grain pattern, cedar can be rough. So, I am concerned about the possible splinter factor. Some species can have pretty tight grain patterns but I think this fence started out rough sawn which make me think that there is a smaller probability that these boards will make good chairs. Once again, I would like to investigate.

As woodworking projects go, this is a pretty simple one. I would guess that I can knock out a chair in a couple of hours. It means that whatever plans I have wouldn’t be derailed significantly to build a couple of chairs. I am thinking that I would use a semi-transparent stain as well. This project will require some new wood as the structural pieces and I would like to blend the overall look to something more uniform.

I suppose the other option is that I could laminate pieces to make thicker stock, but again this would be another experiment. I am not a huge fan of glues and outdoor exposure, but it would be an option and require less new material. Maybe I will selectively remove a couple of boards to check for viability before I commit to this.

End Your Programming Routine: I hate the idea that all of this wood will simply go to the landfill. I would rather see it turned into firewood rather than simply hauled off to the dump. The real problem is that time is money. Nobody from a job perspective has time to break all the panels down, pull the nails and stack it, cut it, store it and market it or even give it away. To top it off, cedar is not the best firewood by a long shot. That being said, if I can efficiently use it that would be my preference.

Recent Comments