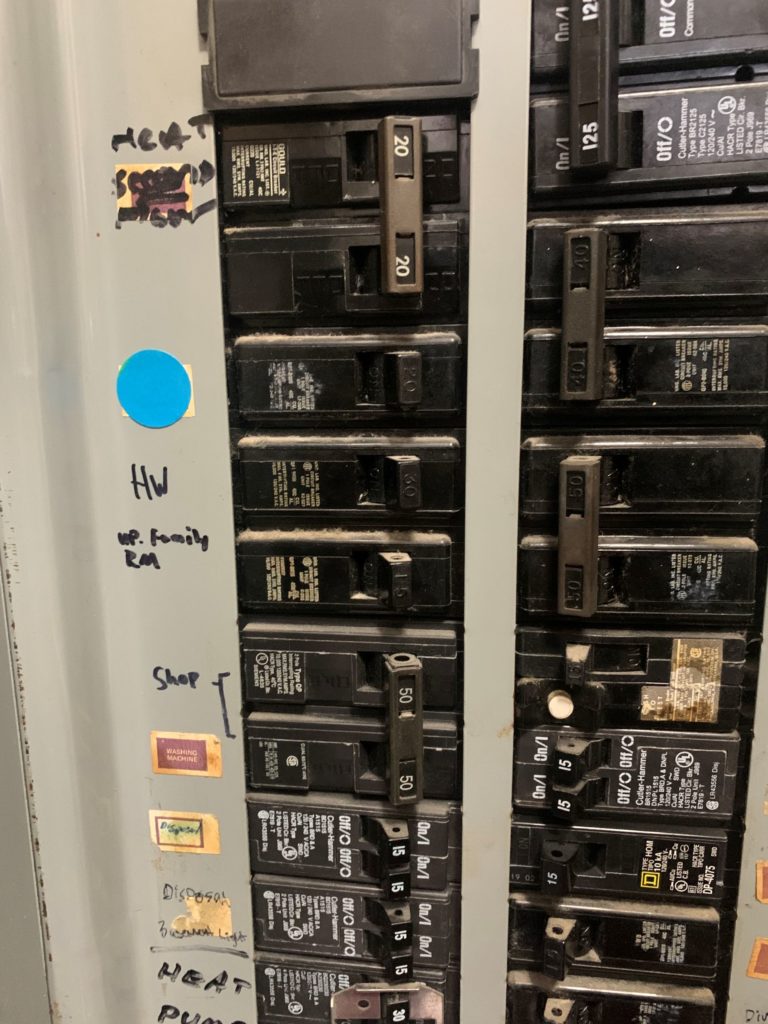

OK, so I underestimated the hassle factor on this. I thought I was going to get off cheap and easy with $30 in parts and an hour of time. First problem, I couldn’t find the breaker. After a bunch of running up and down the stairs, I found out that my breaker panel is actually mislabeled on which breaker actually runs to the water heater.

I figured it was probably a 30 amp breaker, because it was 10 gauge wire coming in to the water heater. The panel was labelled a 20 amp breaker. Now, some years ago, we had some arcing in the panel and we paid an electrician who removed the top level breakers and shoved everything down in the panel. At that time, almost nothing was labeled so I never bothered.

I only label breakers as I find them. Worse case scenario, I can turn everything off with the main on the panel. But, as much a I have dinked around the house, I have never had opportunity to look at every circuit.

After testing to verify the power was finally off, it was time to drain the tank. Hook the hose up and run it to the sump. Open the valve and nothing. Come to find out that the drain valve on the tank is plugged up with mineral build up. So, now I have new problems. How to get the water out of the tank without burning myself or dumping 50 gallons of water all over the floor.

By the time I figured out how to approach this problem, I ran out of time to do what I needed to do. Plus, I needed time to obtain the parts so I spent another $30 on brass tube fittings to build something that could blow air back into the system and clear the drain. That took a couple of hours, but it worked. Finally, after three different attempts, I was able to drain the water heater.

In 2020, when I spent my entire summer remodeling the apartment, I did some water heater work there. I have known since we moved into the house in 2005 that there were a few low risk items that needed to be addressed. One of which was no catchment pan under the water heater. So I bought one. How ever, I wasn’t able to drain the water then either. So, I left it for another time. This was going to be the time.

First, I wanted to get the elements out so I could see how bad the inside of the tank was. Feeling good that I conquered the draining, soon changed to I didn’t have a socket to remove the element. It required a 1 1/2″ socket. So, another trip to the store. I also needed PVC for the drain line, although that was really optional for the initial job. Another $30 for those parts.

I removed the top element an there wasn’t much to see. These tanks are glass lined, so they are pretty impervious on the inside. But when it came to the bottom element, it was heavily corroded and my new $6 element socket quickly met it’s match. It tried penetrating oil, heat and hammering none of them worked. I needed to find a real socket, not the stamped sheet metal one for the most leverage possible.

These are tractor sized dimensions, to the tractor store for tools. Now, add another $40. I also didn’t check my PVC glue before the last trip which was also dried out. I had to get that too. But, finally, I got the bottom element out. All in all, it looked better than I was expecting. That being said, there was definitely some buildup on the elements.

Once drained, I wanted to flush the tank. Ideally, to do that I would get the pan underneath the tank so I could flush without sending water all over the floor. Fortunately, my son is strong enough that he can bear hug the tank while I slid the pan underneath it. I was able to complete the PVC work but ran out of time to actually flush the tank.

End Your Programming Routine: It is nice to have hot water again. I guess the degradation is so slow that you don’t realize what it used to be like. Hot water is continuous throughout my shower and the dishes again. After doing this job, I am convinced that this is a one hour job with the right knowledge and tools. That being said, I overpaid with time and materials. I don’t regret doing it myself because now I know but it wasn’t as cheap or as easy as had planned.

Recent Comments