I suppose this is somewhat of a project update and some sort of analysis. When starting this project, literally months ago I had scoped it to be done by the end of January. I knew that I was going to be travelling in February but now it is getting to the middle of March and I am not done yet.

Now, am I actively working on the project? Yes I am currently in the glue up portion where I am gluing the aprons and the legs together. This means that I am very close to final assembly and finish. This means that the project will be done. However, this is my last week this month so it is likely that this will now run into April.

When I estimated the project at the beginning of the year I guessed that it would take 100 hours for this project. I am not sure that I have spent much more time than that but I think where I went wrong was 100 hours over a month would be 25 hours a week. And that is not really realistic. I am probably logging 4-6 hours a week.

Extrapolate 100/5 would be 20 weeks. That is five months and by that math and hypothetically I am actually ahead of my estimate. However, I borrowed an old crutch of hope, that was wrong. I hoped that my work would accelerate as it often does when I get into things but hope is not a plan.

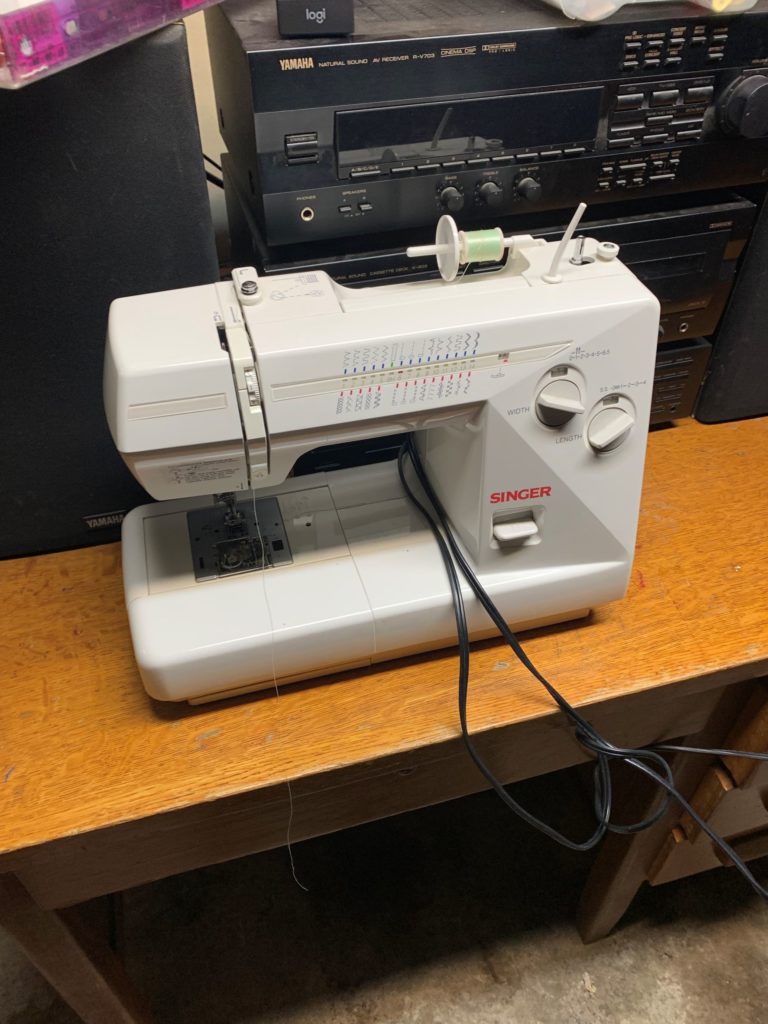

I am enjoying the work and I do believe that it will be worth the effort. So, I am not necessarily wishing it to be over but I am certainly looking forward to moving my stereo system into my office. To that end, I am also looking forward to getting my rain barrel setup as my next project.

While it is not my first, fine woodworking project I would consider myself a novice at it. My mortises and tenons were rough. with loose fit for some. My chisels sometimes were dull, causing some of that roughness. This was my first tapered legs that I have made. I learned some things from the experience for sure.

I guess that you could boil all this down to using realistic expectations. If I had just used my brain rather than hoping I could do this, I would have set clearer expectations and by proxy wouldn’t be disappointed by my results. I knew better.

End Your Programming Routine: It’s like I always say, fifteen minutes a day is still almost two hours a week. This is another trap that I sometimes fall into. Ultimately, I am committed so it will be what it will be. And, it truly wont be that long until I am done, I am just lamenting that we are coming into April and I wanted this done at the beginning of February.

Recent Comments