I am a connoisseur of techno junk. All of that comes off of the secondary market. As a result, you never know what procedures are put in place to protect the former owner. I suspect that companies do some things, but really why would I as a former owner want to put chance out to the universe.

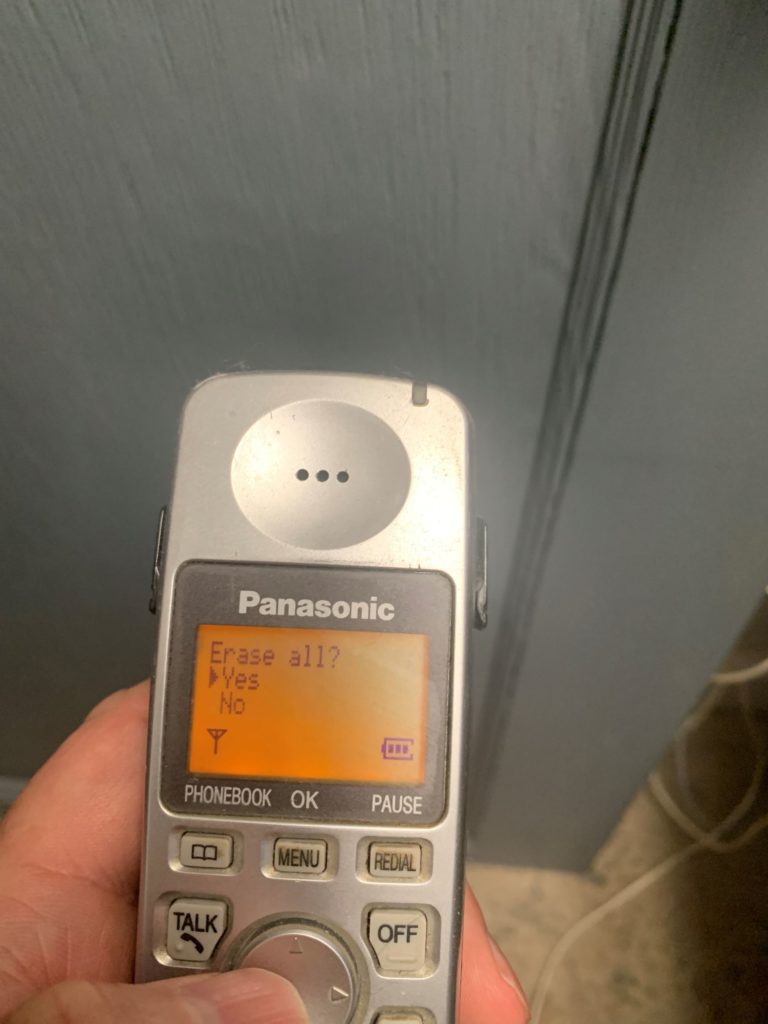

I had our old phone system sitting around for a few months. The reason is because I wanted to clean them before I got rid of them. I will acknowledge that getting any real, usable data and having that fall into unscrupulous hands is a very small possibility. That being said, who would want to buy something with other’s junk on it either? We as consumers need to do our due diligence to protect ourselves as best possible.

I will admit that when I get something second hand that has data on it, I take a look at it. I never intend to do anything with it, but more as a curiosity. Who were these people, what did they do with this, what did they replace it with and those kinds of questions. I never invest much before I start over, I suppose it is that due diligence look.

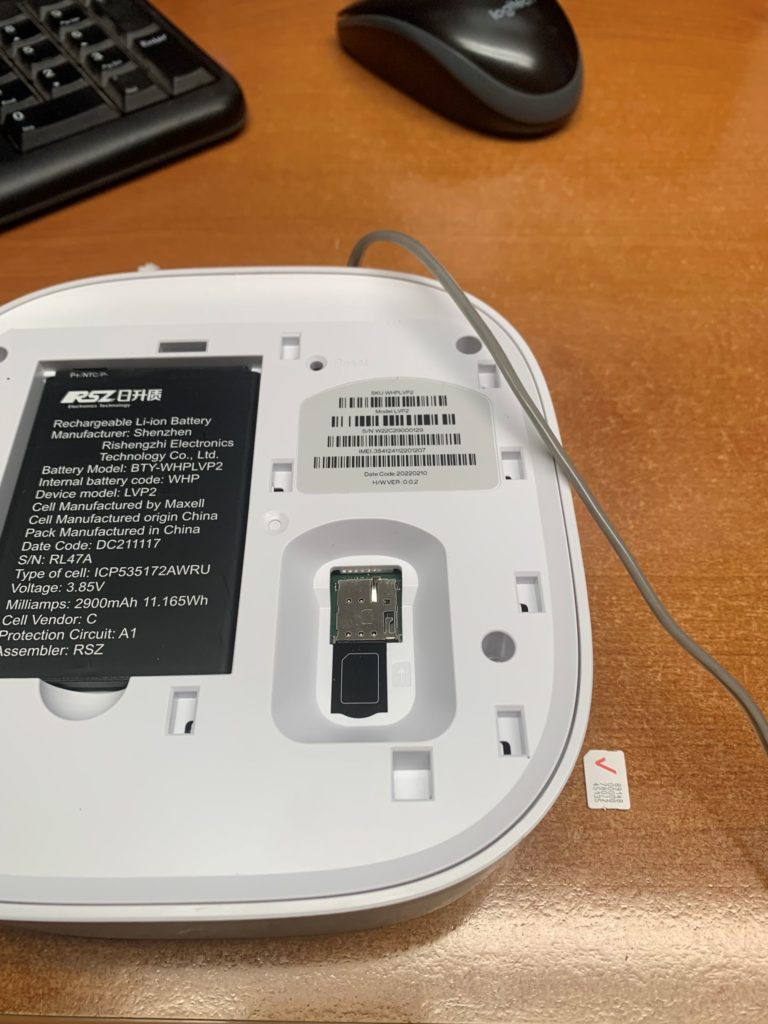

I don’t have anything to hide, but people don’t need to know that I received calls from a household in Germany in 2023. I feel like it is more protecting them, not so much me. The main unit is a cell phone that has a wired connection. So, this is as good as handing over a cell phone to a stranger. I took the SIM card out. Probably, information could be obtained through the provider but at that point, it is out of my hands.

I have sitting in my shop a robotic vacuum. The reason it has not gone to the recycler is that it is still configured to run. This is a device that has a map of my house, down to how the furniture is arranged. It also has a connection to my internet, albeit it is a guest connection. But still, there is no reason just to hand that stuff over to parts unknown.

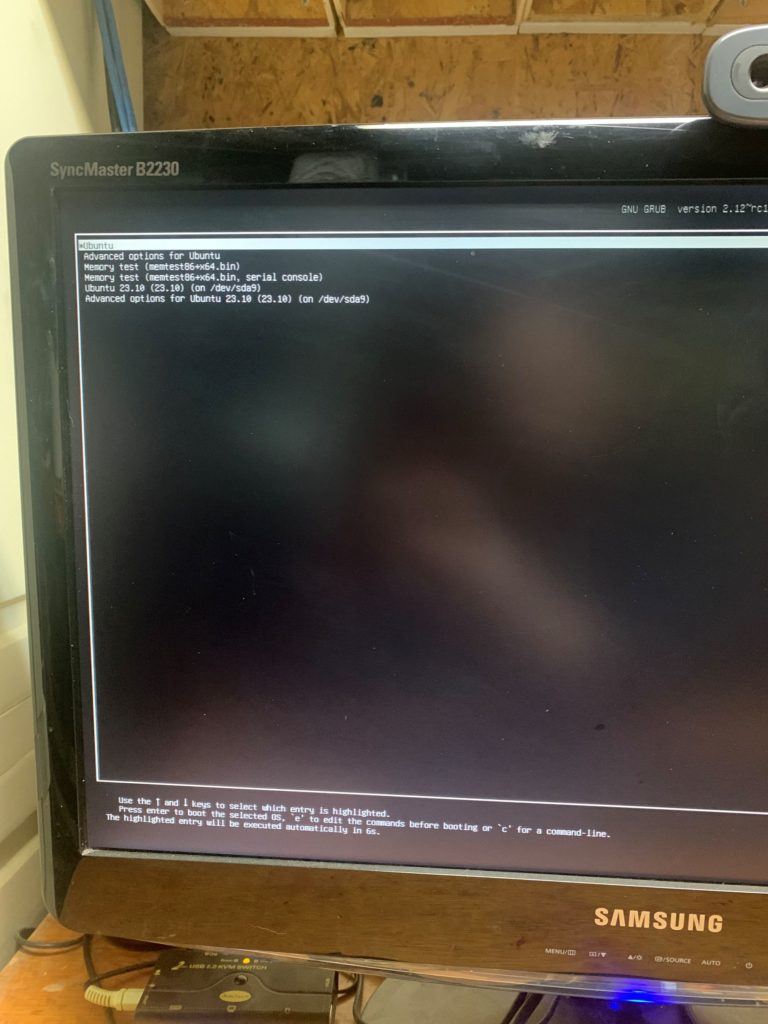

This is a related scenario but I am becoming aware of old devices and vulnerabilities. The rough outline is old applications that are no longer supported by manufacturers offer a potential home for malware. This could be inadvertently installed and get access to a network. I am a little on the fence on what to do here. Probably the best thing is disconnect old devices from the network or segregate to a guest network an protect active data.

That seems like a subject for another day. But in this day and age of everything can connect, everything wants an account and everything is collecting data, it is a good idea be thinking longer term in security strategy. It is not so much the money but the time to deal with all of these things that could be the real killer. My advice is to clean everything you can before disposing of it, no matter the mechanism.

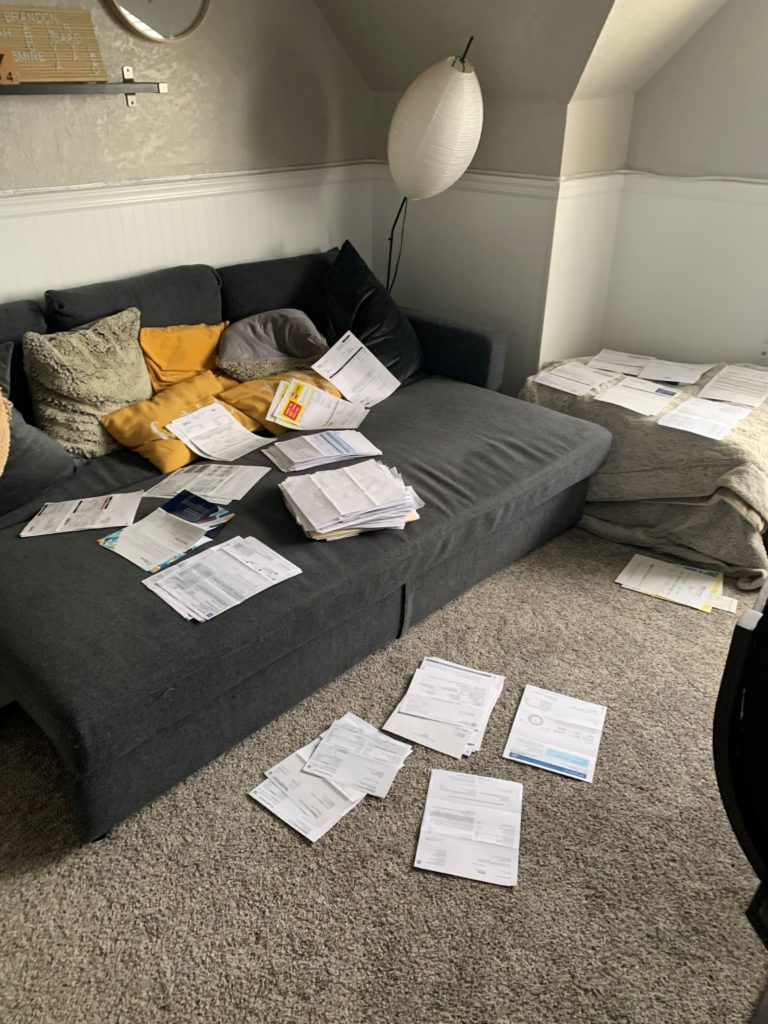

End Your Programming Routine: I used to believe that I have nothing to hide. I still think that is true, but I also think that no doing due diligence with electronics disposal is like leaving a stack of 100 euros laying at a park bench. It may not be immediately useable, but somebody could figure out how to convert it into something that they want. Don’t just surrender potentially valuable information, think about what you are doing and the consequences.

Recent Comments