You know, I suppose that I am lucky. I go to the dentist twice a year. One time I was talking to my dentist and he said that some people have teeth so bad that they have to come in once a month for cleaning. Whatever the chemistry or the diet or the personal habits are, there is enough build-up necessary to have a cleaning session.

A lot of times, your saw blades have the same problem. The quality of the cut is not necessarily the sharpness of the blade, but the build-up of the sap/pitch/crud on the teeth. Not only does that build-up effect the quality of the cut but it also effects the quality of the blade. Meaning, the harder the metal has to work the more heat build-up there is and the more likely dullness and or damage will occur.

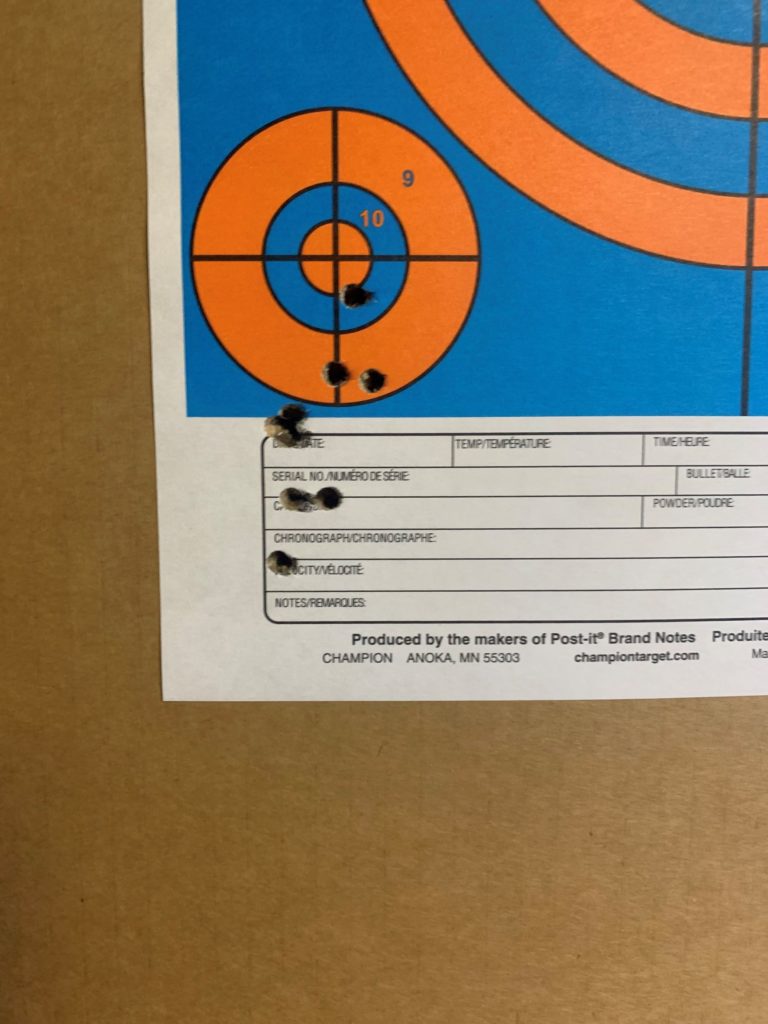

Just like the dentist, I brush my teeth, then I scrape them using something like an X-acto knife and then I brush them again. My picture above is after brushing them once. First, I spray on some simple green. I have the blade in a very cheap automotive fluids pan to contain everything and let them soak for 15 minutes. Then I use a bronze bristle brush like you would find in the gun cleaning section of the store.

When to to this is usually visually apparent. You can see the build-up on the saw blade. Now, I am as lazy as anyone else. I don’t like doing this and it takes away from my productive shop time. So, I make the decision on a task by task basis. If I am cutting construction lumber, then I don’t really care so much about cut quality, but on my woodworking projects, I do care about the finish cuts.

All that being said, I would also be more diligent depending on the quality of the blade. The one pictured is a $40 blade today ($30 at the time I bought it). I suppose that this is nothing to sneeze at but there are much more expensive blades. It is a decent quality blade and cut, but in the end these are consumables.

And with all of that, I am not manic about it. I spend thirty minutes doing the major cleaning and maintenance and then I move on. It doesn’t look like it came out of the box but it works much better than before I cleaned it.

Before I scare anyone off, the frequency of cleaning has a lot to do with what you are cutting. I tend to cut mostly fir, hemlock, cedar and spruce. These are high resin woods where the buildup happens immediately. Working with the American hardwoods like oak, maple, walnut and others the pitch buildup will be significantly less. My air dried fir has hidden pitch pockets that are still liquid so it doesn’t take long to coat everything in pitch (including my fingers).

Up until this point I have been referring to circular saw blades. Band saw blades are effected even more from buildup. When I am re-sawing boards, it is nearly impossible to get a straight cut when the blade is not clean. I do the same process, I just leave the blade on the saw when I do it.

There is probably a lot more to say on the topic of saw blades in general but I wanted to focus on cleaning them today. There are specific products for this job on the market, but Simple Green (or generic substitute) works just fine for me. That being said, I have never tried them so they may work better than what I am doing. There are other products that are meant prevent the problem in the first place. Think of it like Pam for your tools. I worry about that stuff effecting the finish that I eventually put on the wood.

End Your Programming Routine: If you are struggling with quality cuts, take a look at your blade. You might be amazed at what a difference a cleaning will make on the final outcome. You also might need a more appropriate blade for your task, so try cleaning first, then replace if results are not desirable.

Recent Comments