I know that I want to keep this project on course by continuing to provide ‘how to’ information and not just a status report on my projects along with editorials. So, I thought that I would do a mini series on framing. I don’t claim to know everything but I think I know the fundamentals and I think that I know enough to help the layman or uneducated make better informed decisions. So, what is there to know about framing with respect to materials?

The first thing to know is your application. Is the project outside or inside? Will it ever get wet or touch the ground? Is it going to be load bearing? How is it going to be constructed?

Let’s start talking about ‘Outdoor’ versus ‘Ground Contact’ pressure treated lumber. Depending on what part of the country you live in, some of these products may be more or less accessible. Pressure treated lumber has only been around for about forty years or so, so good building practice is always in order and trumps appropriate materials.

You will see at the home center materials marked ‘Outdoor’ lumber. These are wood species that naturally rot and insect resistant like Redwood, Cedar, Cyprus and some exotics. Depending on the species and grade, they are often significantly more expensive than pressure treated. They are also not grade stamped for loads and spans. For those two reasons, their best uses are fences, decking, railings, outdoor furniture and other non-critical applications.

Pressure Treated is usually hemlock in the west or southern yellow pine in the east. These are treated with a solution of what is called ACQ or Alkaline Copper Quaternary. I won’t get into the science of it all, but that treatment helps defer wood deterioration. You can often times identify the materials by their appearance because they appear green or dark brown.

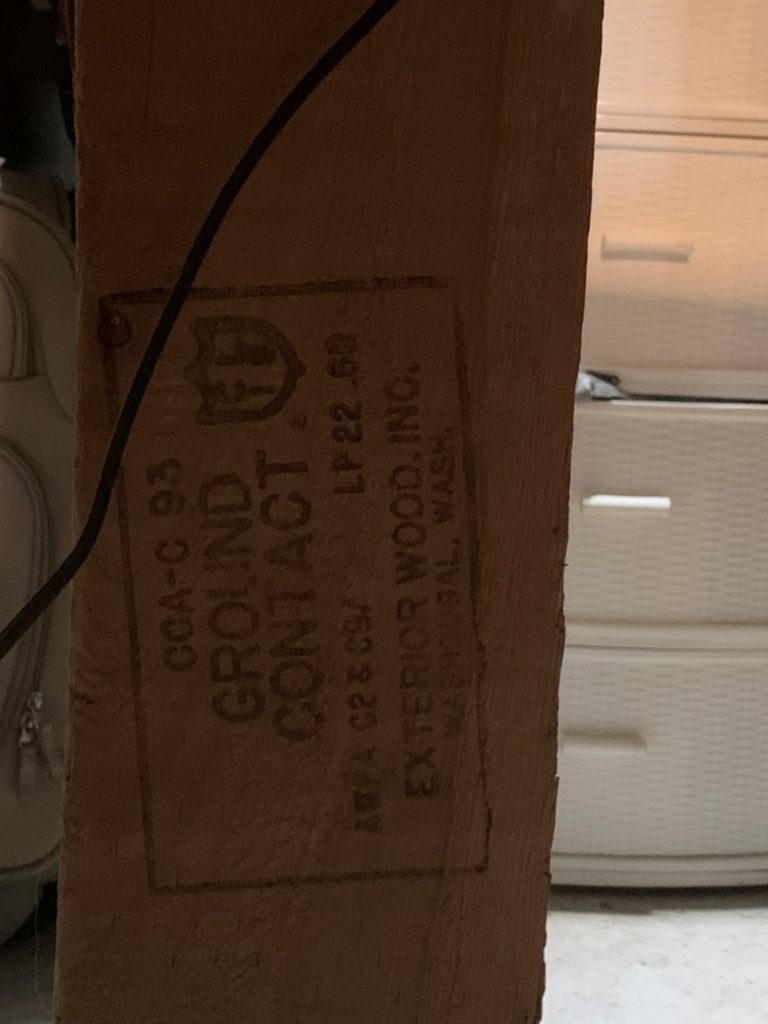

A better way to tell is that the material is stamped or tagged.

I am old enough to remember the big switch from CCA to ACQ in wood treatment which happened in 2004. The reason I bring it up is fasteners. You see, you cant just use any old fastener and expect it to last. What can happen is a galvanic reaction between copper (in the treatment) and iron (in the fastener) will corrode the fastener into nothing.

For that reason, all fasteners should be hot dipped, galvanized or coated (with paint, not vinyl). But not marked ‘bright’ or electrogalvanized which looks very shiny. The same goes for screws. The good news is that is all sorted out now, so if you buy new fasteners you wont have incompatibilities. I still have fasteners from before the switch, so I need to be mindful of where I put them to use.

There are a slew of plates and connectors and other things depending on what you are doing may or may not be necessary. And frankly, it is beyond the scope of the basics. They are referred to as ‘Simpson Ties’ and there are good reasons to use them for hurricanes and earthquakes and even rot protection.

Lastly, pressure treatment does not absolve good building practices. I have seen (and have) many rotten fence posts because water cannot leave the post when encased in concrete. Another thing I do is treat cut ends with canned preservative when using outside because the treatment does not penetrate completely through the board.

End Your programming Routine: There is a lot to know even to get started. Knowing your conditions and application will enable you to get help in selecting the proper materials if you have questions.

Recent Comments